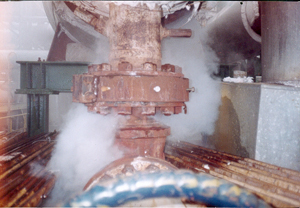

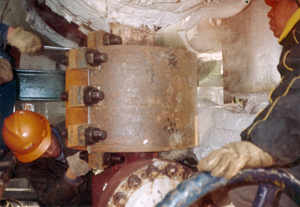

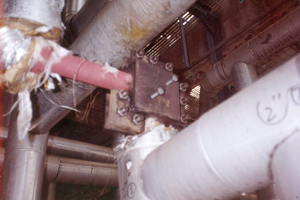

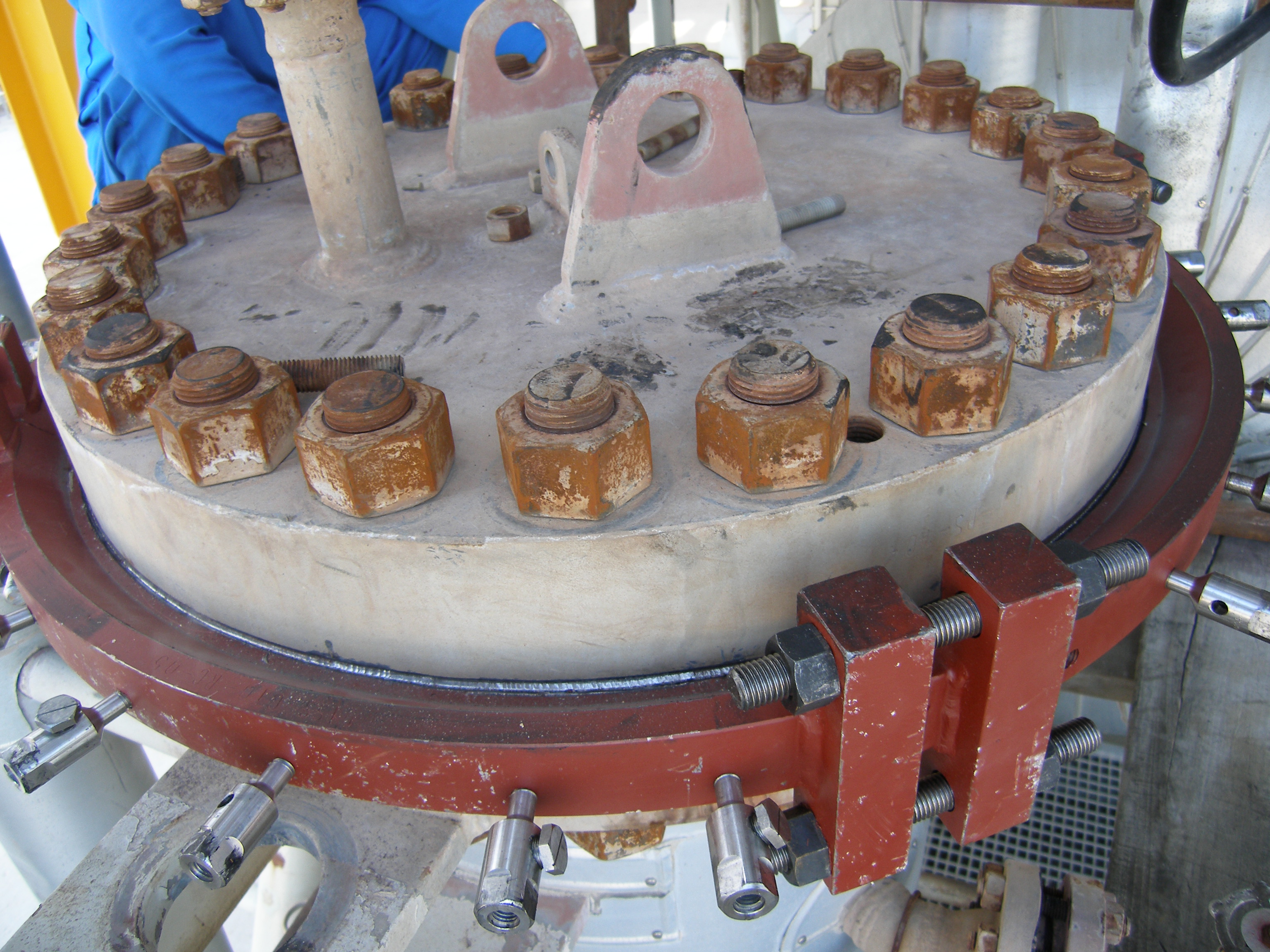

In recent years, through its application in thousands of projects, the Company has accumulated rich experience as well as more mature technique, and therefore boasts unique skills in dealing with more difficult projects. The conduction top clamp developed by the Company has effective sealing dimension for leakage. The insulation clamp is adopted to deal with residual oil, heat-conduction oil and other emplastic medium for leakage sealing, which effectively addresses difficulties in sealing construction in the long run.

The sealing of the oil extracting machine and the pump rod has a close relationship with the security of oil wells, environmental protection and production effectiveness for a given period of time. The filling swing sealing equipment adopted by the Tuha Oil Filed in Xinjiang Uygur Autonomous Region has successfully addressed the problems for oil fields in sealing the pump rod without stopping production.

In the past three months when the Company conducted spot guidance for a petrochemical company, the Company trained a strong professional team and succeeded to seal 162 leakage parts for it. Consequently, the petrochemical company has been equipped with tens of sets of production facilities and become a large-scale enterprise engaged in processing of crude oil with a stable, secure, excellent, satisfactory, long-term operation.

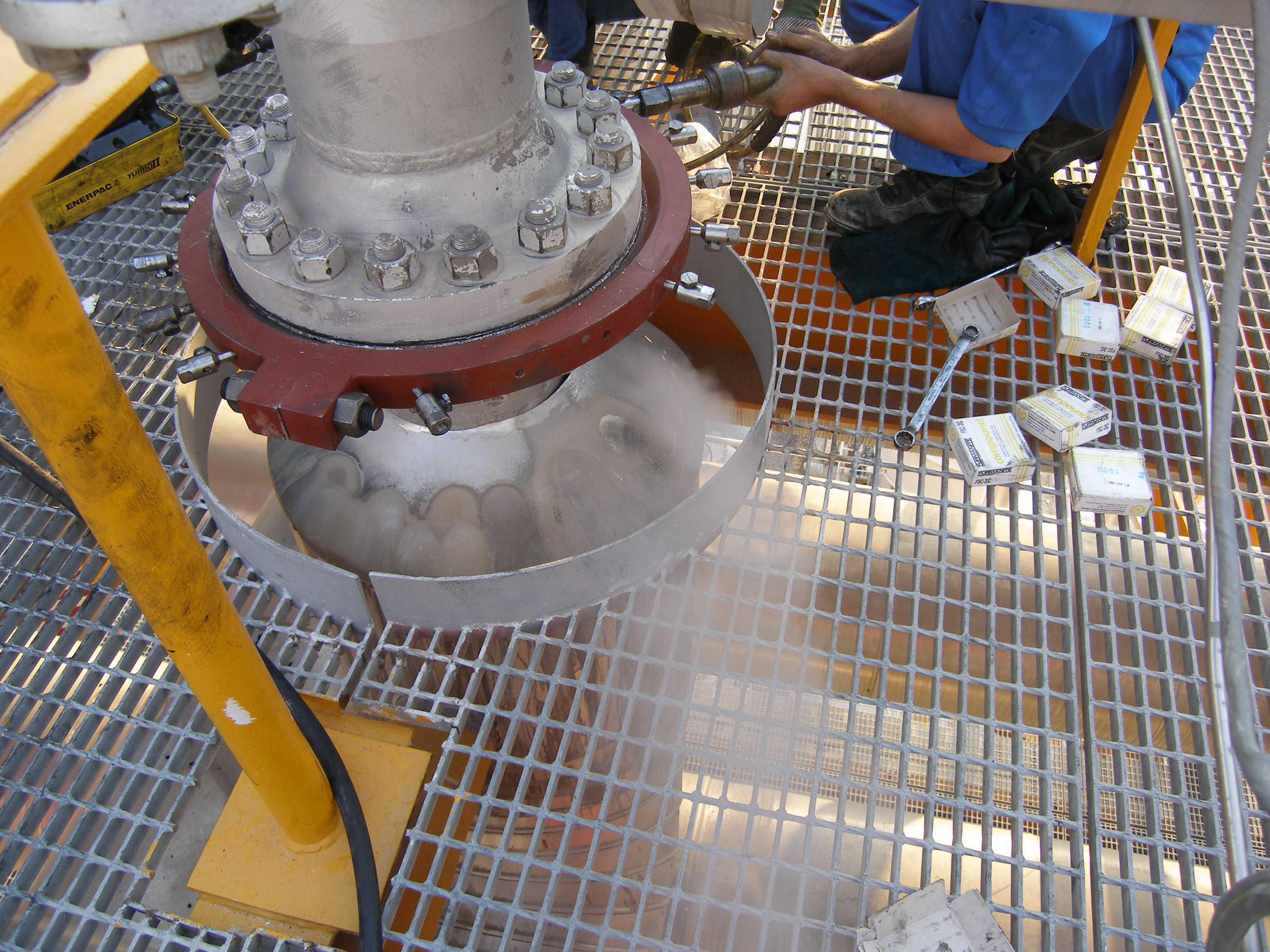

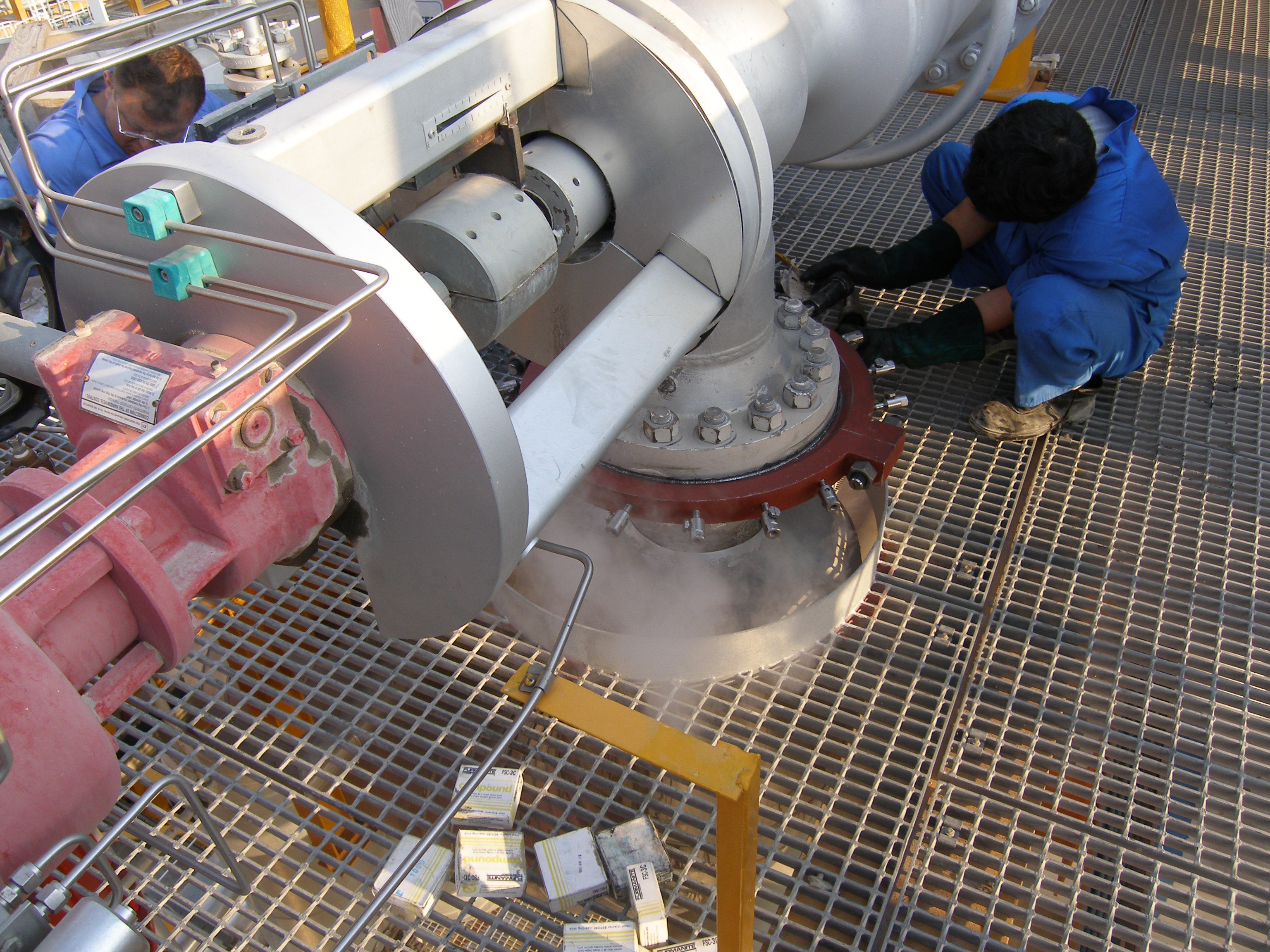

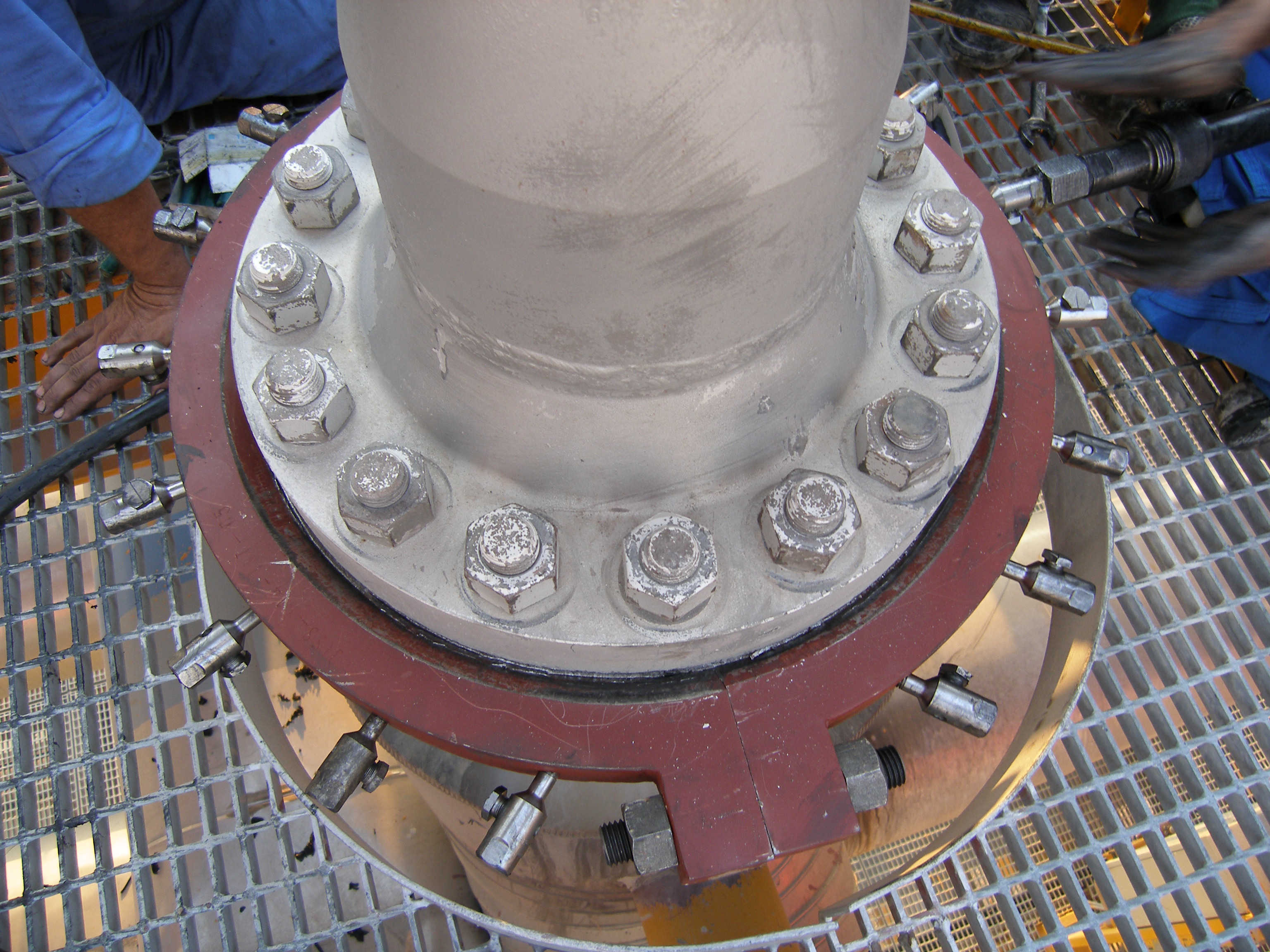

The Company endeavors to expand its business overseas. The above is the construction scene for the TXY-18# sealant purchased by Indonesia from the Company.

Please continue to click the project cases of the Company, where there are detailed descriptions regarding clamp design, construction process and how to select sealants.

Historical Achievement of TXY-Tech

In 1980s, under pressure leak sealing technology was in research and application in the subordinate enterprise of Sinopec. Wang Jinrong, the general manager of Tianjin Xiangyue Sealing Material Co. ltd, has been one of the leaders.

In 1993, sep.

In 1999-Oct. Injectable sealant compound TXY-18#, which was developed by cooperation of TXY sealing material Co. ltd and Wuhan petrochemical plant, was tested and appraised by the CPCC expert panel.

In 1999, Online leak sealing technique was permitted to apply in the pressure vessel and pressure pipe by government laws and regulations.

In 2004, Sep. Wang Jinrong, General manager of TXY Sealing Material Co. Ltd., was awarded the patent for the sealant TXY-18#.

In 2005, Jan. China Association of Plant Engineering established On-line Leak Sealing Technology Center in Tianjin Xiangyue Sealing Material Co. Ltd. Wang Jinrong is appointed as Director.

The regulation for Online-leak sealing operation, issued in 2005 Dec. by AQSIQ, prescribes that operation personnel should go on to the operation or management position after participating practice test and obtaining the certification.

In 2007, Dec. National Board of Boiler and Pressure Vessel Inspectors put forward putting On-line leak sealing technology standards under centralized management by specialized departments. And TXY Sealing Material Co. Ltd. was the lead company for the standards drafting.

In 2008, TXY Sealing Material Co. Ltd set up international marketing department in the company for the promotion of on-line leak sealing technology.

|

China Contact

Tel: +86-22-23111200 Fax: +86-22-23301140 |

TXY-TECH INC, 9894 Bissonet, Suite 987, Houston, TX 77036

Tel: (510) 220-5689 (510) 502-1227 |