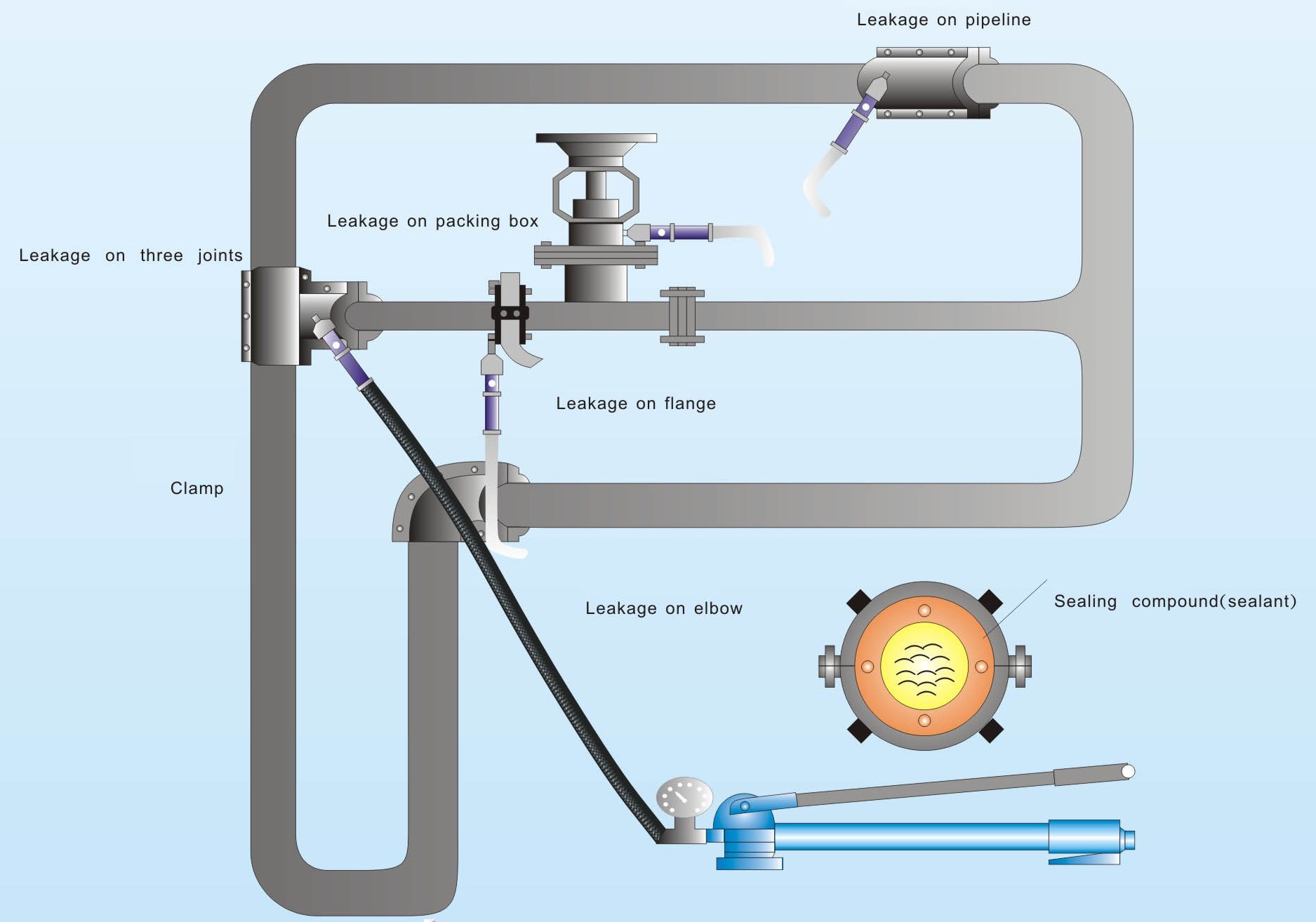

On-line leak sealing technology is widely used in companies with continual producing process, where unexpected leaks may cause an emergent shutdown and bring enormous loss. With on-line leak sealing technology, the leaks, which are normally found at flange, T-pipe, elbow, valve, pipelines, can be stopped quickly and efficiently without affecting the producing process.

When leakage observed or surveyed, we use special designed clamps to enclose the leaking point and build a sealing cavity between the original structure and the clamp. To overcome the system resistance force and frictional force, we use injection gun to fill cavity with sealing compound by high pressure pump. Through sophisticated designing the clamps, the sealants will not enter into the media stream and not influence the media quality but solidify as they fully fill the entire cavity space, building another structure around the original one and stopping the leak.

The economic benefits on-line leak sealing technology brings to manufacture corporation are remarkable. By solving the leaking problem while keeping industrial plant on-line, it saves the plant from being explored to unscheduled shutdown, which is a heavy price to a plant. Instead of replacing your leaking equipment with a new one, an expensive and time-consuming solution, on-line leak sealing technology repairs your equipments while maintaining their system integrity, extending the life of your equipment components. It also protects environment from noise and harmful emissions and avoids explosion caused by leaking combustible media.

Application:

Applicable Temperature:

Applicable Pressure: vacuum – 32MPa.

Applicable Media:

Alkali, Acid, Benzene & Derivatives, Aldehyde, Alcohol, Ketone, Ester & Derivatives, Oil, Gas, Coal Gas etc., in total over 300 chemicals

Applicable Industries: Petroleum, Chemical, Metallurgy, Electricity Power, Pharmaceutical, Fertilizer, Water and Heat Supply industry.

Technology Benefits

Not disturbing the normal producing procedure

Not affecting the original structure and easy to disassemble the clamps

Convenient operation

Cost-effective and environment protection

Broad application in many industries

1. Applications

The technique of pressure sealing without stopping production is a maintenance technique for advanced equipment that was developed in the mid-1970s. We can eliminate leaks in production equipment or piping using temperature and pressure techniques very quickly, safely, reliably and without interruption of the production process. We can eliminate leaks of the valve filling case in several minutes without changing the fillings and the valve can be opened and closed freely. We can use different advanced light special tools and techniques to seal leaks of the flange, straight pipe, three-way pipe, elbow, screw threads and implement walls. We can customize sealing techniques according to local conditions. Our techniques are widely used in various flow work industries including oil, chemical, fertilizer, power, metallurgy, medicine, chemical fiber, gas, water supply and heat supply.

2. Technique characteristics

1) Good in adaptability and widely used for leak sealing to different kinds of media, temperature and pressured sealing structures.

2) We can seal under temperature and pressure without stopping production. The seal process does not affect normal production.

3) The technique does not utilize fire, ensuring safety.

4) Special treatment of the leaking position is not necessary before pressure sealing. That makes the operation more convenient and faster.

5) We do not destroy the original sealing structure. The new sealing structure is easy to disassemble. We can eliminate leaks in the disassembly joint structure including flanges, screw thread joints and filling cases.

6) The technique is adaptable and has a wide application scope. It can eliminate the leaks of nearly all liquids.

7) The technique is reasonably priced and does not require high investment.

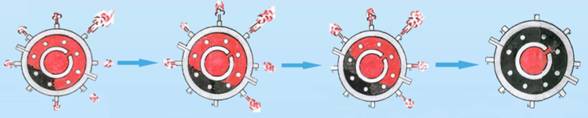

3. Basic Principles

use special clamps containing the leaking part and to set up a suitable airtight cavity together with the original structure. Use higher power from hydraulic pressure system made by special sealing tools than the one from leaking system and the frictional resistance to fulfill the cavity with sealing compound. With the help of higher pressure and thermo-solidification, it achieves leak sealing on the condition of dynamic system and the new sealing structure's been made.

4. Application scope

2) Leaking media: we can eliminate leaks of water, water vapor, air, oxygen, nitrogen, gas, ammonia, liquefied gas, gasoline, diesel oil, kerosene, heavy oil, lubricants, acid, alkali, ester, alcohol, benzene, various heat carriers, hydrocarbon, chemical gas, liquid and all other media.

3) The temperature of leaking media: -195°C--800°C

4) The pressure of the leaking media: vacuum 0--32Mpa(320kg/cm2) or higher.

5. Economic benefits and social benefits

1) The economic benefit of using this technique is to avoid the loss of unplanned production breaks or machine accidents.

2) Avoid resource losses. Most (eighty percent) of eliminated leak points are water vapor leaks. Most are ordinary leaks except the serious leaks that halt production.

3) Decrease the loss of raw materials, supplies and products.

4) Eliminate leaks of flammable and explosive media that ensure production safety by preventing fires and explosions.

5) Reduce and/or eliminate noise and environmental pollution.

6) Easy and fast operation that saves maintenance time and reduces repair costs.

6. Services

1) Technique consultation: answer customer questions about the sealing technique theory and various implementation obstacles.

2) Technique and training: includes jig design, the techniques of leak elimination, various implementation methods, safety techniques, the use of special tools and sealant selection principles and methods. We teach students using classroom instruction, technique videos, demonstration and practice until they can seal leaks under pressure independently.

3) Local emergency service: If there are serious leaks at customer facilities we will send professional sealing implementation staff to eliminate leaks quickly while ensuring production safety.

4) Pressure sealing tools:

(1)special tools for injection sealant: We supply different models of manual, pneumatic and liquid pressed machinery tools for injecting sealant.

(2)special implementation tools: includes small pneumatic tools, electrification tools, belt-fastening tools, special clamps, various tie-ins and accessories that make pressure sealing more convenient.

5) Sealant: we supply multiple models of sealant that are suitable for various media in various temperature ranges from-195°C--800°C.

6) We supply special protection articles for pressure sealing: special overall work uniforms, water- proof uniforms, heat-proof leather uniforms, water-proof gloves, safety caps with masks and noise-resistant ear plugs.

|

China Contact

Tel: +86-22-23111200 Fax: +86-22-23301140 |

TXY-TECH INC, 9894 Bissonet, Suite 987, Houston, TX 77036

Tel: (510) 220-5689 (510) 502-1227 |